Why Woodworkers Across Australia Are Switching to Robertson® Screws

Share

For decades, woodworkers around the world have argued about the “best” type of screw. Phillips has dominated hardware stores, Torx has a loyal fan base, and some still cling to flatheads out of pure nostalgia.

But in recent years, a growing number of Aussie furniture makers, cabinet builders, and DIY legends have been making a very deliberate switch—to Robertson® square-drive screws.

And once you’ve used them, the reason is obvious:

Robertson screws just work better.

1. Zero Cam-Out: Your Bit Stays in the Screw

Anyone who has ever stripped a Phillips head knows the frustration of cam-out.

The driver slips, the screw head gets destroyed, and your project—and your sanity—take a hit.

Robertson’s patented tapered square socket pulls the bit in tight, dramatically reducing cam-out. That means:

-

More control

-

Fewer stripped heads

-

Less pressure needed

-

Faster, smoother driving

For precision joinery and cabinetry, this alone is enough to convert most woodworkers.

2. One-Handed Start: A Game Changer

One of the most impressive benefits is the one-handed screw start.

Slide a Robertson bit into the screw and it literally sticks—you can hold it horizontal, vertical, or even upside-down without dropping it.

Great when you’re:

-

On a ladder

-

Working in tight spaces

-

Looking after long runs of decking

-

Needing that extra hand to hold your timber steady

No other screw gives that much stability right from the start.

3. Perfect for Hardwoods and Australian Conditions

Australian hardwoods—Jarrah, Merbau, Spotted Gum—can be brutal on fasteners.

Robertson screws handle the job beautifully thanks to:

-

Self-centring tips

-

Deep threads

-

Hardened steel

-

Consistent bite

Whether you’re building furniture, framing, or decking, they provide clean penetration with reduced splitting and tearing.

4. Better for Tools, Better for Hands

Because the square drive transfers torque more efficiently, you don’t need to apply as much downward pressure. That means:

-

Less fatigue

-

Less slipping

-

Less chance of the drill jumping and chewing into your timber

The square-drive design also helps your drill bits last longer—saving money in the workshop over time.

5. Trusted by Pros Worldwide—Now Growing Fast in Australia

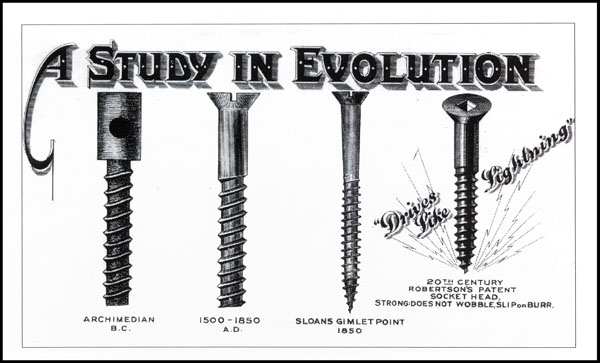

Robertson screws have been the standard in Canada for over 100 years, used in cabinetry, construction, and fine furniture making. The automotive industry adopted them early because of their reliability under repetitive use.

Today, more and more Australian woodworkers are discovering why the Canadians love them.

And thanks to Screw it Screws, they’re now easier than ever to access across Australia.

Why Woodworkers Choose Screw it Screws

At Screw it Screws, we stock the full range of genuine Robertson® screws—perfect for cabinet makers, carpenters, and furniture builders who demand durability and precision.

Our screws feature:

-

True Canadian-spec square drive

-

Heavy-duty steel

-

Anti-cam-out design

-

Premium coatings for long-term performance

-

Packs for tradies, furniture makers, and DIYers

Whether you're building a table, fitting cabinetry, or doing intricate joinery, Robertson is quickly becoming the preferred screw in workshops across Australia.

Ready to Upgrade Your Woodworking?

Once you try Robertson® screws, you’ll never go back.